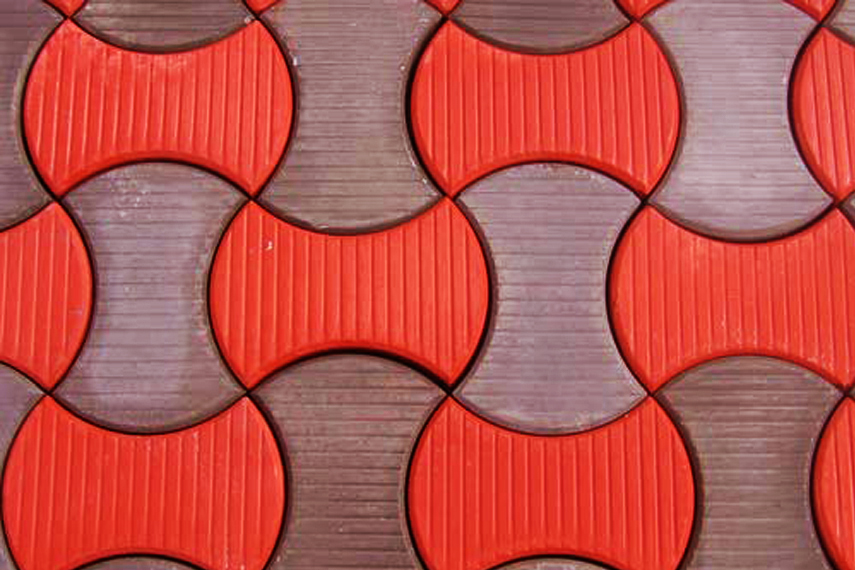

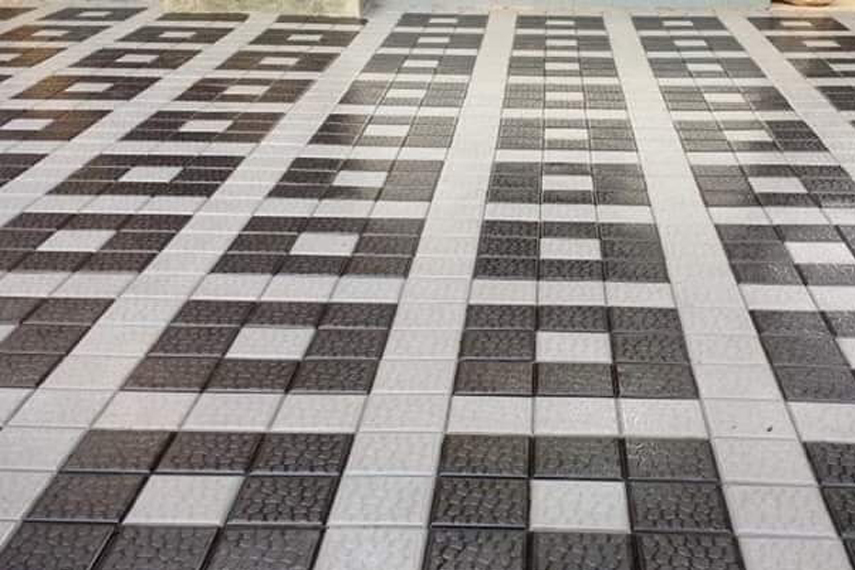

Cement products, Bricks, Interlock (mould and hydrolics), Tiles Industry

Our Products

SET FAST

PRODUCT DESCRIPTION:

Set Fast is a liquid which acts as a Setting hardener for Concrete. Fast hardening compound for Concrete hardening liquid, also known as anti-wear concrete liquid, is a substance that is used to smooth concrete surfaces and polish them.

The goal of employing this material is to boost concrete's high mechanical strength so that it can endure abrasion, impact, and other damage.

PROPERTIES

APPLICATION

ADVANTAGES

DIRECTION FOR USE

Before adding to the dry mix, Super con is blended in the appropriate quantity of measuring water. It should be applied during the cement and fly ash slurry process.

DOSAGE

Required dosage of Set Fast has to be arrived at site by practical trials. The dosage is dependent on temperature conditions, type of cement, type of acceleration required. We however recommend dosages of 1 to 2 percent by weight of cement.

STORAGE

Set Fast liquid should be stored in a cool place and protected against moisture.

SHELF LIFE

Storage time should not exceed 6 months from receipt of delivery.

PACKING

Set Fast is available in 60 Kg & 250 Kg Barrel

Our Products

SUPERCON

PRODUCT DESCRIPTION:

Super con which acts as a Setting hardener for Concrete. Fast hardening compound for Concrete hardening, also known as anti-wear concrete liquid, is a substance that is used to smooth concrete surfaces and polish them. The goal of employing this material is to boost concrete's high mechanical strength so that it can endure abrasion, impact, and other damage.

PROPERTIES

APPLICATION

ADVANTAGES

Our Products

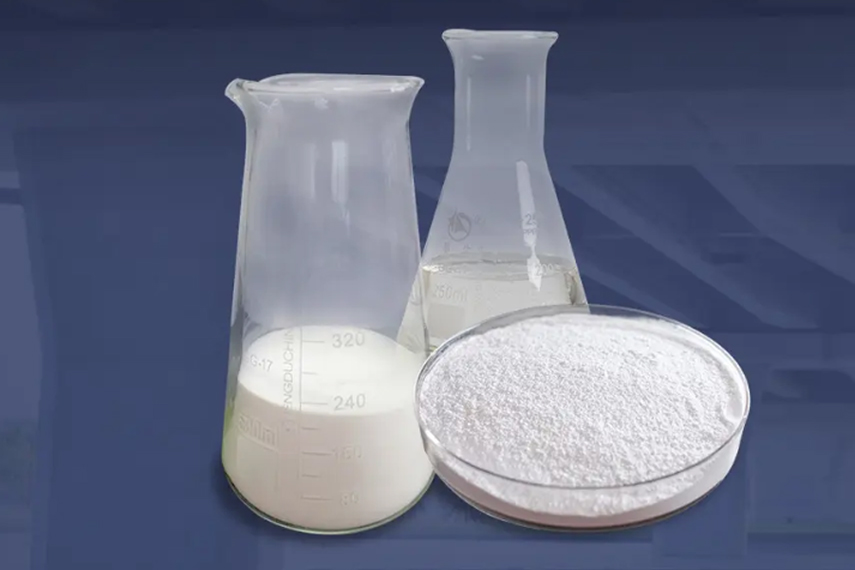

PLAST PCE 902

A NEW GENERATION PRODUCT

(High strength, high range water reducing superplaticising admixture for precast Concrete)

PRODUCT DESCRIPTION

We are engaged in offering a wide range of super plasticizers which are widely used to enhance the plasticity or fluidity of the concrete and to increase its strength. Apart from our range of we are also manufacturing the third generation of superplasticizers i.e. Ultraplasticizers called the Polycarboxylate Ether (PCE). Polycarboxylate Ether show extremely high water reduction in concrete with improved workability and increase in strength by almost 20-30% depending on use. Polycarboxylate Ether Superplasticizer show good workability in concrete at even at water cement ratios as low as 0.23.

PROPERTIES

APPLICATION

ADVANTAGES

DOSAGE

Optimum dosage of Plast PCE 902 as guide a dosage range of 200 ml to 250ml per 50kg of cementations materials.STORAGE

Store material in normal room temperature keep away from direct exposure from sunlight and humidity. Seal tight the container if not in use.SHELF LIFE

Storage time should not exceed 6 months from receipt of delivery.PACKING

Plast PCE 902 is available in 250 kg barrel.

Our Products

PLAST PCE - 802

PRODUCT DESCRIPTION:

PCE 802 is dried based on polycarboxylic ether with uniform partials, low water content, good Stability polycarboxylate. Superplasticizer manufactured through optimizing molecular group configuration and synthesis process. Due to its special molecular structure, it can reduce the dosage of water It is suitable for mortar and concrete containing special cement with high flow ability and strength.

PROPERTIES

APPLICATION

Dosage

Required dosage of Supercon Plus has to be arrived at site by practical trials. The dosage is dependent on temperature conditions, type of cement, type of acceleration required. We however recommend dosages per 50kg bag of Cement 200ml to be added. Increase the quantity of Supercon Plus for increasing the strength.

Packing

Appearance - White powder

Bulk density - 400-700kg/m3

Moisture in (%) - ≤ 5%

pH value - 7.0-9.0

Chloride - ≤ 0.05%

Water Reduction Rate in (%) - ≥25%

ADVANTAGES

DOSAGE

STORAGE

SHELF LIFE

PACKAGING

Our Products

PLAST PCE 850

(High strength, high range water reducing superplaticising admixture for precast Concrete)

PRODUCT DESCRIPTION

We are engaged in offering a wide range of super plasticizers which are widely used to enhance the plasticity or fluidity of the concrete and to increase its strength. Apart from our range of we are also manufacturing the third generation of superplasticizers i.e. Ultraplasticizers called the Polycarboxylate Ether (PCE). Polycarboxylate Ether show extremely high water reduction in concrete with improved workability and increase in strength by almost 20-30% depending on use. Polycarboxylate Ether Superplasticizer show good workability in concrete at even at water cement ratios as low as 0.23.

PROPERTIES

APPLICATION

TECHNICAL SPECIFICATION

Test - Result

Appearance - Clear White to reddish Brown liquid

Relative density - 1.06 ±0.02 at 25C

Chloride ion content - < 0.2%

PH - ≥ 6

ADVANTAGES

DOSAGE

Optimum dosage of Plast PCE 850 as guide a dosage range of 200 ml to 250ml per 50kg of cementations materials.

STORAGE

Store material in normal room temperature keep away from direct exposure from sunlight and humidity. Seal tight the container if not in use.

PACKING

Plast PCE 850 available in 250 kg barrel.

Our Products

SUPERCON PLUS (PCE)

POLY CARBOXIDE ETHER

PRODUCT DESCRIPTION

Supercon plus which acts as a Setting hardener for Concrete. Fast hardening compound for Concrete hardening, also known as anti-wear concrete liquid, is a substance that is used to smooth concrete surfaces and polish them. The goal of employing this material is to boost concrete's high mechanical strength so that it can endure abrasion, impact, and other damage.

PROPERTIES

APPLICATION

ADVANTAGES

DIRECTION FOR USE

Before adding to the colour mix and dry mix, Super con is blended in the appropriate quantity of measuring water. It should be applied during the cement and flyash slury process.

DOSAGE

Required dosage of Supercon plus has to be arrived at site by practical trials. The dosage is dependent on temperature conditions, type of cement, type of acceleration required. We recommend dosages 200 ml to 250ml per 50 kg cement Bag.

STORAGE:

Supercon plus should be stored in a cool place and protected against moisture.

PACKING:

Supercon Plus is available in 250 Kg Barrel.

Our Products

Mould Cleaner

A New Generation Mould Cleaner for Cement Product Industries. Ready to use mould cleaning agent.

Uses

To provide quick & easy cleaning of moulds with low corrosion.

Advantages

Technical Specification

Specific Gravity : 1.05gm/cm3

Appearance : Transparent like water

Application

Apply Mould Cleaner on mould surface simply by using Brush. Keep it for 2 to 3 hrs. & clean it by pressurized water.

Our Products

Lacquer

Polish for concrete products. It is useful in pavers Blocks. Main advantages are Glossy finish, Durable on tiles, pavers blocks, Transparent coating.

Our Products

Plast CP - 211

(Plasticizer for concrete products)

Our Products

Plast ESN

(Plasticizer for concrete products)

Our Products

Plast ES (Granules)

(Super plasticizer for concrete products)

NEW RANGE OF PRODUCTS

Our Products

Plast PCE 811

(New generation polycarboxylic ether, superplasticising admixture)

Our Products

Polyplast

(New generation polysulphide sealent)

LIGHT WEIGHT / AAC / CLC / BLOCKS

Our Products

CLC - FA

(Foaming Agent for light weight blocks)

Our Products

CLC - Hardner

(Fast hardening compound for CLC blocks)

Our Products

Soluble Oil

(It is used In manufacturing echo friendly products like light weight Autoclayed Aerated Concrete Blocks)

Benefits:

Our Products

Foam Generator

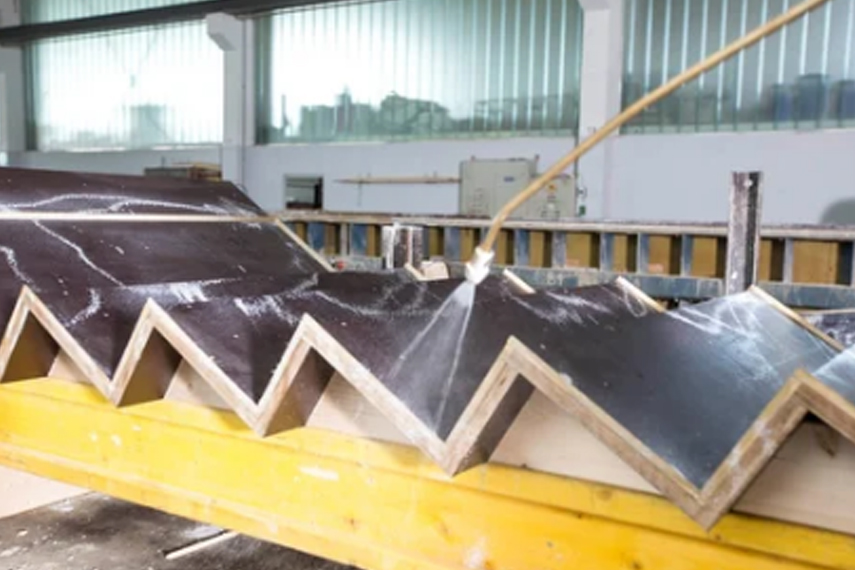

(It is used for making Foam from Foaming Agent for CLC)

MOULD RELEASE OIL (Shuttering Oil)

Our Products

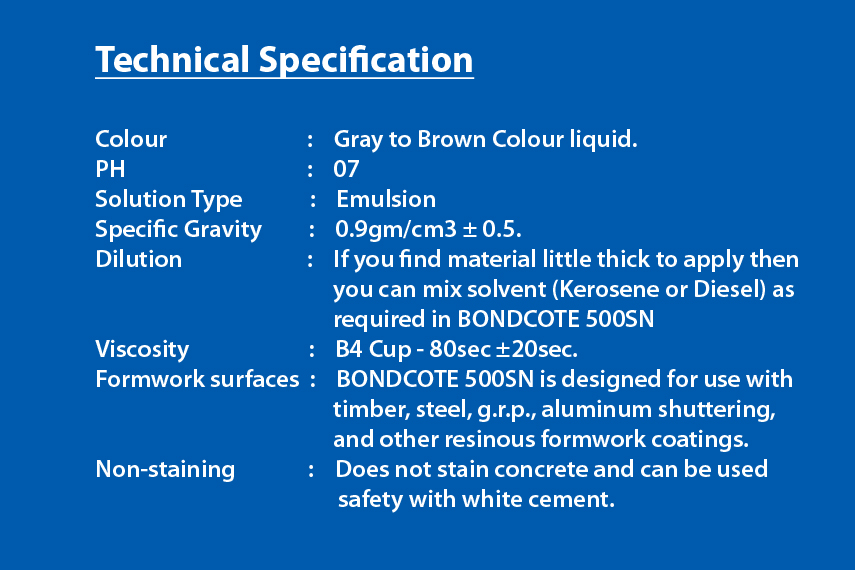

BONDCOTE 500SN

(Solvent dilutable shuttering Oil / mould release agent)

Uses

To provide quick, clean and easy stripping of moulds and formwork and ensure high quality fair-faced and stain-free concrete.

Advantages

Description

BONDCOTE 500SN is a blend of selected mineral oil and non hazardous chemicals, specially formulated to produce release properties which are superior to those of conventional BONDCOTE 500SN is supplied as liquid, ready for direct application on site. The chemically reactive components in BONDCOTE 500SN provide a water repellent interface which protects formwork and ensures an even colour and texture of the cast concrete. In addition to preventing adhesion of the cement matrix to the formwork, BONDCOTE 500SN will allow air to escape from the interface during concrete placing and vibration. This release of air minimizes surface blemishes and results in a substantial reduction in remedial costs.

Application Instruction

Preparation of new moulds

No preparation is necessary but if extensive re-use of timber moulds is envisaged, it is advisable to protect all new surfaces from alkali attack which can result in a very short usable life. Steel moulds require no special treatment other than the removal of rust or oil, although wetting out may be improved by lightly abrading the surface.

Preparation of used moulds

All traces of adherent material either concrete or previous oil deposits must be removed prior to use. Moulds previously used with BONDCOTE 500SN will require only light brushing as the presence of fine dust will improve the wetting out properties of BONDCOTE 500SN. This will usually result in improved release properties on the second and subsequent uses of the mould.

Coating

BONDCOTE 500SN can be applied by brush or conventional mould oil sprayer. If a mould oil sprayer is used care should be taken to ensure that a fine nozzle is fitted as BONDCOTE 500SN should be applied in a light continuous film. If BONDCOTE 500SN is over applied, excess material should be allowed to drain and then carefully removed from the bottom of the mould by means of a sponge or cloth. Pools of BONDCOTE 500SN should not be allowed to dry otherwise surface retardation of the concrete may occur. Unlike conventional mould oils, BONDCOTE 500SN does not possess residual release properties so it is important prior to each occasion of use, all areas of the mould are recoated. Particular attention should be paid to coating mould rims in order to avoid adhesion of overspill cement slurry.

Cleaning

Should the sprayer be subsequently required for a solvent or oil based product, it is advisable to wash out with clean water and allow to drain. Brushes should be washed well in clean tap water after use.

Coverage

Coverage rate is dependent on the porosity of the mould material being used. The coverage rate and the form release properties of BONDCOTE 500SN will be reduced if the Formwork is of an old/worn nature.

Application:- Don't use Cotton cloth and Roller Brush while using the product i.e Bondcote 500SN

Instruction: Stir well material before use

Important: Irrespective of performance of the material, Odour (Smell), Colour, Viscosity, Thickness, Density & Sp. Gravity may vary.

Our Products

Mould Release Agent MRA

(Mould Release Oil for removal of shuttering)

Our Products

Mould Release Agent MRA - ALU

(Mould Release Oil for Aluminium shuttering)

Our Products

Mould Release Agent MRA- Steam

(Mould Release Oil for Steam curing Products)

Our Products

Mould Release Agent MRA - SD

(Use full for FRP Moulds, Fibre Moulds, AAC and all other Moulds)

Our Products

Silicon Emulsion

(It is a water dilutable mould release agent for rubber moulds.)

Our Products

MRA CP

Ready to use shuttering / mould release agent

To provide quick, clean and easy stripping of moulds and formwork and ensure high quality fair-faced and stain-free concrete.

Our Products

Mould Release Agent MRA - CLC

(Mould Release Oil for CLC)

ROAD AND IRRIGATION INDUSTRY

Our Products

Plast AP 430

(Superplasticizer for concrete)

Our Products

Plast AP 501

(Plasticizer for concrete)

Our Products

Plast AEA 600

(High performance Air- entraining & plasticizing admixture for road curbs & canal lining in Irrigation projects.)

Our Products

Curing Compound WE

(Wax Emulsion)

INFRASTRUCTURE DEVELOPMENT PRODUCTS

Our Products

WPC - L

(Water proofing liquid)

Our Products

WPC - P

(Water proofing powder)

Our Products

Add Crete

(Bonding Agent / water proof coating)

Our Products

Maxcare Wall Putty

(Cement based wail putty)

Our Products

Bond It (No Hacking Aid)

It is a powerful concrete bonding agent ideal for use as a primer for cementations repair systems. Bonding Agent is specially formulated as a plaster bonding agent for pre-treatment of smooth backgrounds.

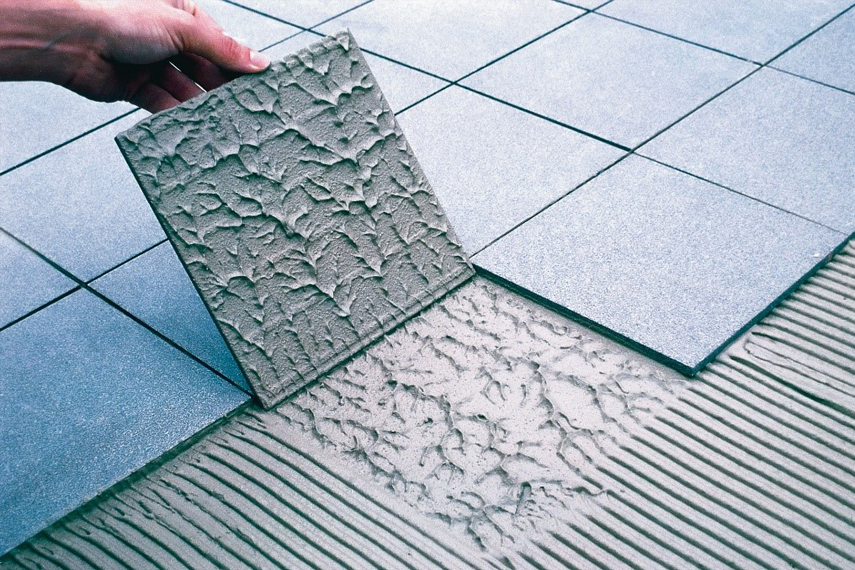

Our Products

Tile Adhesive (TOT)

(High performance Tile Fixing Adhesive for internal wall / Floor)

Our Products

Tile Adhesive HD

(Heavy Duty Fixing Adhesive for Vertical Cladding & Tile-on-Tile Applications)

Our Products

Tile grout (Joint filler)

Our Products

Masonry Mortar

(A New Generation Thin-Bed Mortar for AAC & CLC Blocks.)

Our Products

Plaster New Generation Thin-Bed Mortar AAC & CLC Blocks

Advantages

INDUSTRIAL USE PRODUCTS

Our Products

Grout (Non Shrink grout)

Our Products

Floor Hardtop

(Non metallic abrasion monolithic surface hardening compound)

Our Products

Metallic Floor Hardner

Provide extra toughness to your floor with our industrial standard non-oxidizing, heavy duty metallic floor hardener

DRY MIX MORTAR INDUSTRY

Our Products

RD Powder (AKULPOL-9192)

It Is a hard dispersible polymer powder for very good tensile adhesion strength on inorganic surfaces combined with good workability.

Applications

Our Products

SMF Powder

Our Products

Akulcel CF

POWDERED CELLULOSE FIBERS

These are powdered cellulose fibers. They are water insoluble cellulose.

Application

Our Products

Akulcel 4800

(Modified hydroxyethyl methyl cellulose)

Reduction in water demand in drymix mortar hence increase strength or reduces cement content.

Application

Our Products

Plastment

(Hardner for concrete products)

Pottasium F Humate shiny flakes super soluble 98%

Naturally An Indian Product

AGRI GOLD

PRODUCT DESCRIPTION:

Humic acid is a Powder organic plant growth stimulant and soil conditioner based on active humic acid (potassium humate). It is a bioactive growth stimulant, especially for sandy and heavy clay soils. It is a permanent humic substance which cannot be easily decomposed by soil microorganisms. Humic acid is miscible with other operating fluids, prepare test mixture before use.

Humic acid has a stimulating effect on plant growth in the soil and especially on stronger root development. This improves the absorption of nutrients. An increased root biomass remains in the soil, which contributes to the development of further permanent humus. For plant strengthening, the living conditions for useful soil microorganisms are improved

BENEFITS

FIELDS OF APPLICATION

It is suitable for all types of crops

USAGE OF HUMIC POWDER 98%

TECHNICAL SPECIFICATION

Test and Results

Appearance - Black shiny Powder

Humic acid ( Dry base ) - 98 %

K2O - 15% to 20%

Fulvic - 20%

pH of solution - 9

Density - 1.06 g/ml